Industrial Engineering managers are essential members of the team. They play an important role in leading staff members and improving production output. This includes managing the factory floor's layout and design, and overseeing implementation of processes and procedures. Aside from providing technical expertise and knowledge, they also help organizations develop new products.

The Industrial Engineering Managers are responsible to develop and maintain efficient manufacturing processes. This requires knowledge about the most recent trends in robotics and automation. They are responsible for ensuring compliance with health and safety standards and monitoring and maintaining industrial processes. They are responsible for ensuring that raw materials and consumables are used properly. They also conduct space and workflow studies. The manager is responsible for implementing all work projects. These include cycle time reductions, product cost reductions, and process improvements. They also manage preventative maintenance.

This manager collaborates with other groups to develop new processes, improve efficiency, streamline operations, and create new partnerships. He or she is also responsible for the design and installation, as well as renovations to facilities. Managers are responsible for communicating technical information with non-technical stakeholder as part of their project management. A manager is responsible for securing resources and making site visits to suppliers' facilities. He or she advocates for team members and ensures quality compliance guidelines.

Industrial engineering managers must be motivated, creative, and able solve problems. They must be able climb and walk for up to 12 hours per day, as well as be able handle extreme temperatures. In addition, they must be able to communicate effectively with all levels of employees.

Industrial Engineering Managers must have a degree in engineering or a related field. They must also have at minimum five years of relevant experience. Some employers prefer candidates with postgraduate education. You may also need specific skills like project management or logistics.

Industrial Engineering Managers oversee the design and development of new products and processes. They are skilled in problem solving and quality improvement. They are also able to work in a team setting. The best manager is one who is able and willing to help employees grow.

Industrial engineers excel in streamlining operations. They are proficient in manufacturing processes and have the ability to meet deadlines. They have expertise in recruitment, human resources and logistics as well vendor and supplier relations. They are proficient in setting goals, administering procedures, and creating budgets. They are also able to prepare strategies to increase the efficiency of engineering projects.

Industrial Engineering Managers are responsible for overseeing new manufacturing lines and operating equipment. They are responsible for developing plans to implement new equipment or operating methods according to established standards and guidelines. They will also be responsible for overseeing waste elimination plans. They are also responsible in analyzing the factory's labor productivity.

Industrial Engineering Managers can help improve productivity and develop new products. They also have the expertise to manage human resources. They can also help develop and improve the efficiency of existing processes.

FAQ

What is the responsibility of a manufacturing manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They must also be alert to any potential problems and take appropriate action.

They should also know how to communicate with other departments such as sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

How is a production manager different from a producer planner?

The main difference between a production planner and a project manager is that a project manager is usually the person who plans and organizes the entire project, whereas a production planner is mainly involved in the planning stage of the project.

What is the best way to learn about manufacturing?

Practical experience is the best way of learning about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

What is meant by manufacturing industries?

Manufacturing Industries are companies that manufacture products. Consumers are people who purchase these goods. This is accomplished by using a variety of processes, including production, distribution and retailing. They manufacture goods from raw materials using machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

How can manufacturing reduce production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes both planning for capacity and quality control.

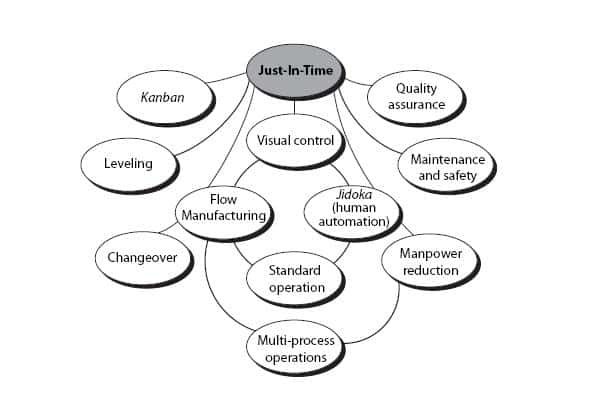

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. Six Sigma aims to reduce variation in the production's mean value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If you notice a large deviation, then it is time to fix it.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. These variations can also be classified as random or systematic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. These are, for instance, random variations that occur when widgets are made and some fall off the production line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. You should then test the changes again after they have been implemented. If they don’t work, you’ll need to go back and rework the plan.