As a logistics coordinator, you will ensure that the goods arrive at the destination they are supposed to be. As a logistics coordinator, you will make sure that the goods reach their destination on time. Our article provides more information on logistics. You'll also learn about the role of a customer service specialist, Inventory analyst, and supply chain manager. Listed below are some of the top jobs that you can find in logistics.

Logistics coordinator

Monster offers thousands of opportunities to find logistics coordinator jobs. This job requires lots of hands-on experience. Candidates with minimal experience can usually take up training through an internship or apprenticeship, although they may also need to have some industry experience. You may be interested in a job as logistics coordinator if you have previous experience.

Customer service specialist

Customer service specialists manage and deliver customer service. They maintain contact with customers, coordinate inland transport, and address customer concerns and complaints. They manage customer relationships and also coordinate appointments, record special service requirements, and schedule transportation, warehousing and other activities. As a customer service specialist, you will also coordinate and document all necessary documents to ensure the delivery of goods on time and within budget.

Inventory analyst

An Inventory Analyst is responsible to maintain service level and improve inventory productivity. Their primary responsibilities include the overall order fulfillment for TSC Feed programs, as well as managing the day-to-day activities of inventory replenishment. They manage the inventory levels of their product categories and support assortment and merchandise plan. They analyze trends and data, and plan article-site replenishment in stores. They can also be involved in marketing and promotion activities. They are often responsible for analysing sales data and creating new business strategies.

Supply chain manager

The role of a supply chain manager involves managing the flow and movement of materials from suppliers to manufacturers and customers. This job requires a wide variety of skills. A bachelor's is often required. Some employers also prefer candidates with master's degrees in business administration. There are various ways to qualify for a supply chain manager job. Learn more about this career. A business administration associate's degree is a good starting point if you want to work in supply chain management.

Freight agent

Your cargo and freight agent responsibilities should be included in your job description. Potential applicants will be able to see the main responsibilities for this job in the job description. To attract qualified applicants, use strong action verbs. You should also provide a detailed list with qualifications that you require to fill the job.

FAQ

What is the job of a logistics manger?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should also ensure enough stock is available to meet demand.

What are the four types of manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

What does warehouse mean?

A warehouse is an area where goods are stored before being sold. It can be an outdoor or indoor area. Sometimes, it can be both an indoor and outdoor space.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three types principally of lean manufacturing:

-

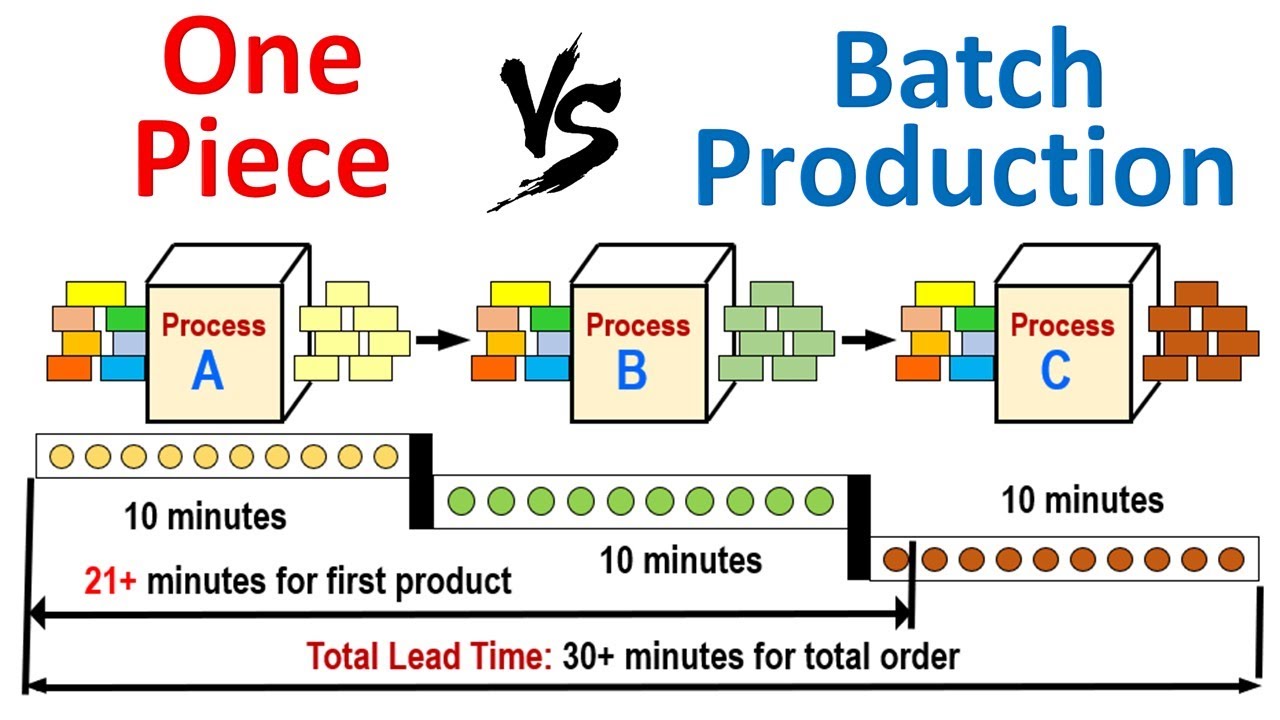

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.