Jobs in wind turbine manufacturing

There are many tasks required to manufacture wind turbines. These jobs include assembly of towers, blade epoxies, and gears. Some wind turbine manufacturing businesses also use third-party vendors to manufacture components. Wind turbine components can be huge so they must be moved quickly and efficiently. Teams of logisticians or rail freight drivers are needed by companies to complete this task.

A bachelor's degree is usually required for jobs in wind turbine manufacturing, but some positions require a master's degree. Wind turbine manufacturing jobs require both engineering and environmental engineering specializations. Entry-level engineers will need advanced computer skills and experience, in addition to a degree. They usually work with more experienced employees to ensure quality control and accuracy. They might also be responsible for more complicated projects.

Manufacturing of wind turbines: Processes

The main components of a turbine's wind turbine are the blades. Each blade consists two faces joined together with integral shear webs. The blades can be supported by a shell fairing or a box spar. These structures are strong enough to withstand edgewise and flipwise loads. The spar resists the edgewise bending caused by wind pressure and gravitational forces. These forces are met by the blades.

Blades can be made from many different materials. Although fiberglass is most popular for commercial blades of wind turbines, aluminum as well as lightweight woods and other materials are used. The blades can then be covered in foil and joined to tubes which pump resin.

Competitors in Wind Turbine Manufacturing Industry

While Chinese manufacturers are a growing force in the global wind industry, they are not yet the dominant player. Chinese turbine manufacturers have struggled to dethrone incumbents in developed markets. They might still be able expand their overseas activities, if they make investments in local manufacturing.

While large turbine makers are increasingly outsourcing parts, many are also choosing to build components on their own. This comes with both advantages as well as disadvantages. Vestas, a Colorado-based company that manufactures wind turbines towers for US third-party projects, has adopted this strategy. The agreement allows the tower plant to utilize up to 25 percent of its production capacity and supports 100 local jobs. Quality control is a problem with this approach. Some components from offshore suppliers have had problems in the past. These include gearbox failures, blade cracking, and gearbox failures. Many offshore foundations are even made from poor quality steel.

Wind turbine manufacturing poses safety and health risks

Wind turbine manufacturing is a hazardous industry. Safety and health are paramount. A variety of hazards can be presented to workers that could cause serious injuries, or even death. Fortunately, there are ways to reduce the risk, including proper training and routine inspections. These are some tips for keeping employees safe when working in a manufacturing wind turbine facility.

One of the most common hazards in wind turbine blade manufacturing is the exposure to harmful gases, vapors, and dust. To reduce the risk of exposure, workers should wear respirators and must be properly trained in using them. Good training is key to ensuring that workers are protected from the elements.

FAQ

What is production plan?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also contain information on achieving the best results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to outline what you want to film. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. You might decide you need a car, but not sure what make or model. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

Once you have found the right vehicle, you can think about adding accessories. What about additional seating? Perhaps you have someone who needs to be able to walk around the back of your car. Maybe you'd like to change the interior from black to a white color. These questions will help you determine the exact look and feel of your car. You can also think about the type of shots you want to get. What type of shots will you choose? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have established all the details, you can create a schedule. You can create a schedule that will outline when you must start and finish your shoots. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. Everyone knows exactly what they should do and when. If you need to hire extra staff, you can make sure you book them in advance. You don't want to hire someone who won't show up because he didn't know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects take only a few days while others can last several weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Multiple shots at the same location can increase costs and make it more difficult to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, it is important not to overestimate the amount that you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

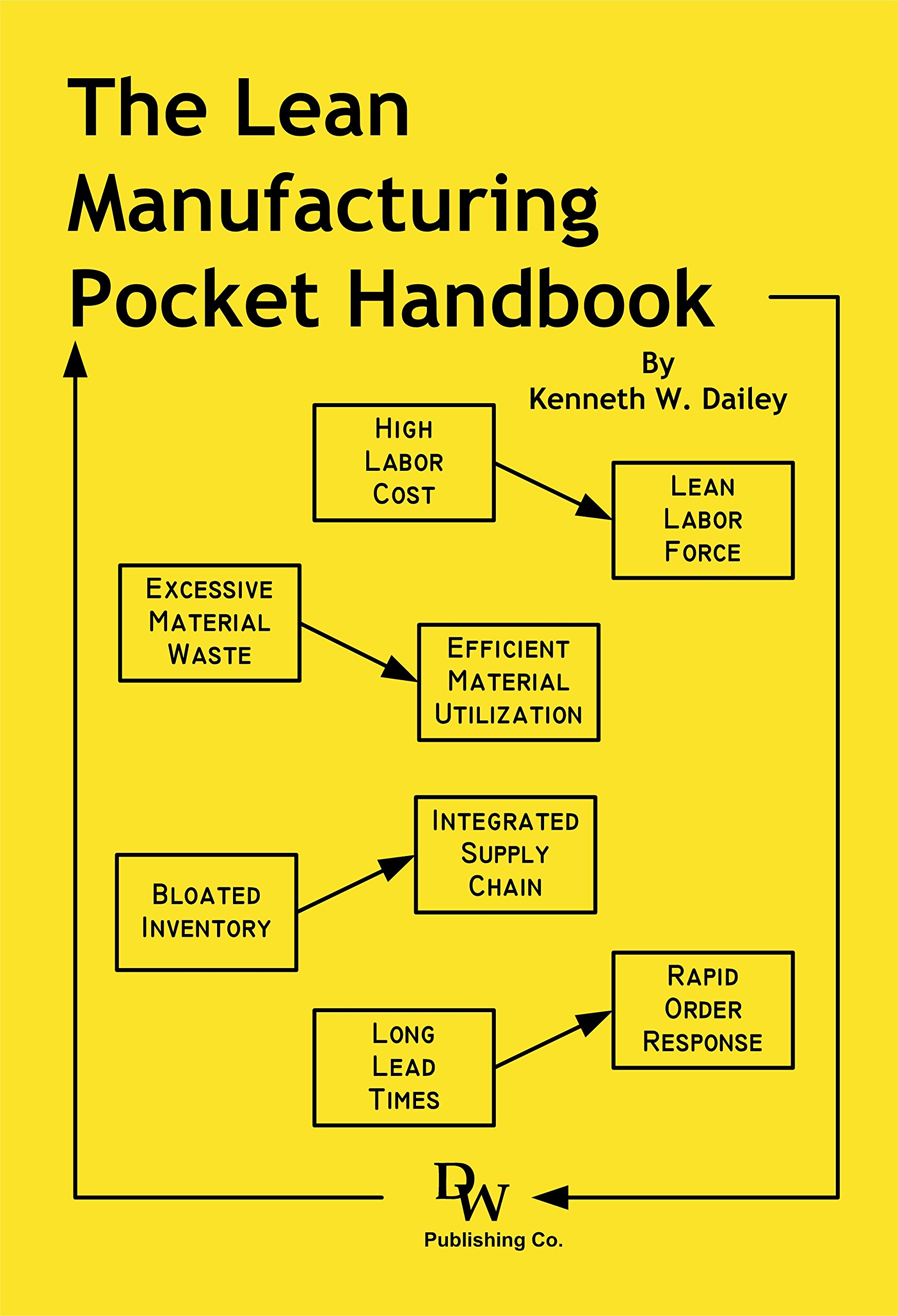

How does manufacturing avoid bottlenecks in production?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for both capacity requirements and quality control measures.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It focuses on eliminating variation and creating consistency in your work.

What are manufacturing and logistic?

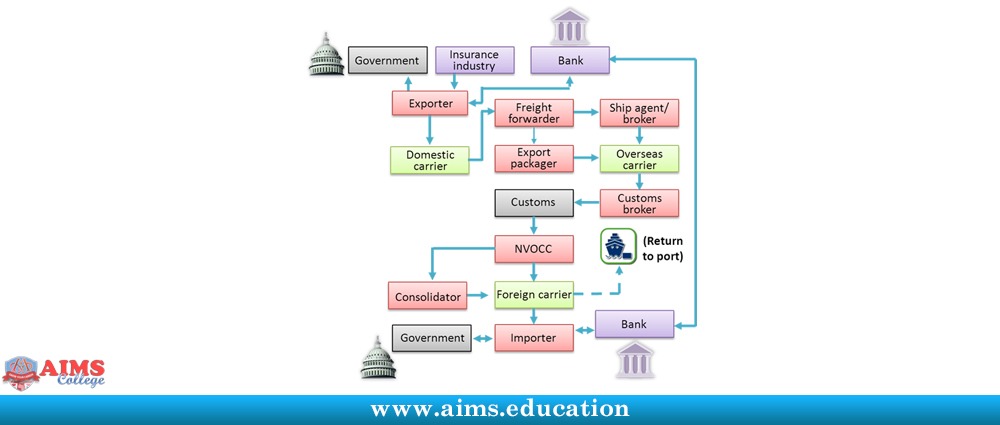

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation was the first to develop the 5S approach in 1954. It assists companies in improving their work environments and achieving higher efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. By sorting, for example, you make it easy to find the items later. When items are ordered, they are put together. You then organize your inventory in groups. You can also label your containers to ensure everything is properly labeled.

Employees must be able to critically examine their work practices. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To be successful in the 5S system, employees will need to acquire new skills and techniques.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.