You will need to have a variety of sales engineering education requirements if you are interested in selling high-tech items. The field is rapidly expanding, so you'll need to keep up with the latest technology and trends to land a job. A good knowledge of the technical aspects of your products is essential, and you will need to be able to communicate these to your customers.

Sales engineers might specialize in one of many fields such as laboratory equipment or scientific instruments. A bachelor's degree typically in engineering or computing science is necessary. Many companies prefer to hire people with advanced degrees. Additionally, you will need experience in customer-facing positions.

A well-rounded sales engineer is someone who has excellent interpersonal skills and a solid working knowledge in sales strategies. They also need to have the ability of building strong relationships with customers. To be persuasive in sales presentations and to communicate with salespeople, you will need to have the ability to do so. This kind of knowledge is usually gained through professional and personal experience.

A mentor is someone who has extensive industry experience. It's common for a sales manager to spend time in the office. He or she can provide valuable advice and guidance and teach you the ins and outs of your company's culture.

Networking is another key factor in a successful career as a salesperson. Networking is a key to a successful sales career. It allows you to learn about new technologies, and can help you find work. Networking can help you gain more knowledge about your industry.

Sales engineers should be self-motivated and possess excellent negotiation and communication skills. They need to be able to listen and understand customers' needs in order to close deals. Sales engineers are responsible for the marketing and production of products. They must be able understand how to market the product's benefits to customers who might not be as technical.

The field of sales is one of the most rewarding and lucrative in the business world. You will be solving problems for customers and feeling proud that your skills are helping others succeed. This job can be stressful and challenging. Sales engineers often earn high salaries.

A strong resume is necessary to secure a position as a sales manager. An effective one should include a summary of your accomplishments, details about your educational background, and a few relevant certifications. You may also want to include work history and dates of employment on your resume.

Although sales engineer education requirements vary from industry to industry, most companies prefer candidates who have an advanced degree. A certificate in project management, a specific skill that can be used to sell, can make you stand out as a professional salesperson.

A sales professional with experience in sales can make a good move to get into the field. Although you can still get a job as a salesperson with a bachelor’s degree in chemistry/business, you will be more successful when you get a master’s or doctoral level degree.

FAQ

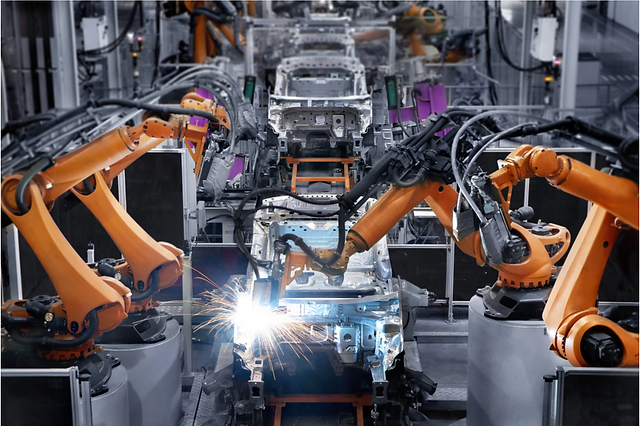

Is it possible to automate certain parts of manufacturing

Yes! Yes. The Egyptians discovered the wheel thousands and years ago. Robots are now used to assist us in assembly lines.

Robotics is used in many manufacturing processes today. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Automation can be applied to manufacturing in many other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What are the responsibilities of a production planner

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They ensure that the product or service is of high quality and meets client requirements.

How can manufacturing efficiency improved?

First, identify the factors that affect production time. Next, we must find ways to improve those factors. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you have identified them, it is time to identify solutions.

What skills are required to be a production manager?

Being a production planner is not easy. You need to be organized and flexible. Effective communication with clients and colleagues is essential.

What is meant by manufacturing industries?

Manufacturing Industries are those businesses that make products for sale. The people who buy these products are called consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They make goods from raw materials with machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was created in Japan by Taiichi Ohno during the 1970s and 80s. He received the Toyota Production System award (TPS), from Kanji Toyoda, founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing is based on five principles:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three types principally of lean manufacturing:

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.