People who wish to become industrial engineers must have strong math skills, a background and ability to solve complex problems. These individuals can work in different sectors, including manufacturing, construction, and health care. They could be found in offices or on the production floor.

Industrial engineers are responsible for analyzing production processes, developing manufacturing techniques, and improving efficiency. They also develop quality control procedures. They may also set manufacturing standards and train workers. If you are interested in a career as an industrial engineer, it is important to be able to work with others. They should have a passion for improving efficiency and streamlining processes. They should have strong leadership and communication skills. They should also be adept at problem solving.

Industrial engineers design cost analysis systems. They also create systems that make robots more efficient. They also use data analysis to determine if processes have been optimized. They could also be responsible for developing manufacturing standards and design guidelines. They may also design procedures for equipment and inventory management, as well as create documentation. They might also present their plans via oral presentations or written reports.

Industrial engineers can work in factories, offices, or warehouses. They may also travel to their clients' sites. They may be required to work in noisy and cramped areas. They may also need safety clothing. Sometimes they will need to work more than normal in order to meet production deadlines.

Industrial engineers are responsible for designing and implementing processes, ensuring that they operate efficiently and that the products are of high quality. They may also resolve production problems. Some industrial engineers also start manufacturing companies. They may also have to train new employees and make sure they understand how to work properly. They may also have to make sure that raw materials meet quality standards before they are used in manufacturing.

In order to manage industrial production processes, industrial engineers collaborate with other departments. They may also specialize within a specific engineering field. They might be required to work in a noisy and cramped environment. They may be required to travel to factories or other construction sites in order to collect data.

You can become an industrial engineer by learning or working in industry. They may then move into management. They might open their own consultancy firms or become technical specialists in a particular field. They may also specialize in quality control procedures or facility planning. They may also be responsible designing production layouts. They might also be responsible for creating wage and salary administration programs. They may also be responsible for scheduling deliveries based on production forecasts, storage and handling facilities, and maintenance requirements. They can also travel to other areas and complete administrative tasks. They can also supervise technicians.

Industrial engineers can work for companies or as consultants. They can work for a company or for a consulting service, and may work up to 40 hours per week. If they provide technical support to a company, they may work longer than 40 hours.

FAQ

What is the role of a manager in manufacturing?

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should be alert for any potential problems in the company and react accordingly.

They should also be able and comfortable communicating with other departments like sales and marketing.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

What are the goods of logistics?

Logistics refers to the movement of goods from one place to another.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They can also track shipments in transit and monitor quality standards.

How can we increase manufacturing efficiency?

The first step is to determine the key factors that impact production time. Then we need to find ways to improve these factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them all, find solutions to each one.

How can we reduce manufacturing overproduction?

Better inventory management is key to reducing excess production. This would reduce the time needed to manage inventory. By doing this, we could free up resources for other productive tasks.

You can do this by adopting a Kanban method. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing is about eliminating waste from all stages of the production process. Anything that does not contribute to the product's value is considered waste. These are some of the most common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Exceed materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What does it take for a logistics enterprise to succeed?

A successful logistics business requires a lot more than just knowledge. Good communication skills are essential to effectively communicate with your suppliers and clients. It is important to be able to analyse data and draw conclusions. You must be able manage stress and pressure under pressure. In order to innovate and create new ways to improve efficiency, creativity is essential. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

You must be organized to meet tight deadlines.

What kind of jobs are there in logistics?

There are many kinds of jobs available within logistics. Here are some examples:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives are available to answer customer calls and emails.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

What is the role and responsibility of a Production Planner?

Production planners ensure all aspects of the project are delivered within time and budget. They make sure that the product and services meet client expectations.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

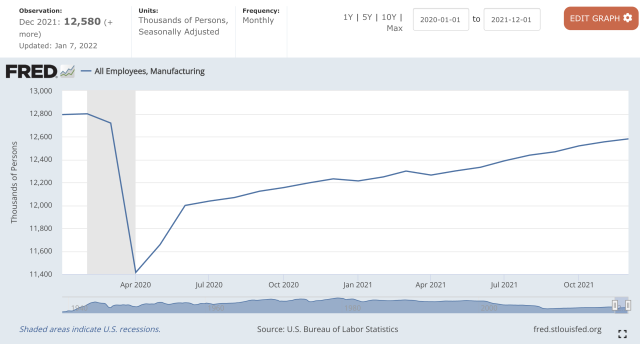

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It is about eliminating defects and waste from all stages of the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely used in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Lean manufacturing is based on five principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three main types:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.