Those who wish to become a drafter need to have a lot of technical knowledge and have the ability to translate their designs into technical drawings. They must also be able work well with others to achieve the best results. They might also need to be able to read and use specific software programs. They might also need the ability to use engineering formulas in order to calculate measurements.

Drafters typically work for architectural and engineering firms. They are responsible for creating plans for buildings, structures, as well as other products, using computer-aided engineering (CAD) software. Although they may work independently, many of these professionals work in teams to create unique designs. These professionals often work full-time but can also do a variety jobs. It depends on which company they work for they might have to work overtime in order to meet deadlines.

Drafters typically obtain an associate's degree in drafting from a community college or a technical institute. After completing their associate's degree, they can go on to a 4-year program at university. Depending on the course they take, they may be able to transfer their degree to a bachelor's degree.

In addition to a drafting degree, drafters may also need to have professional experience. For practical experience, they might be asked to work as interns at a company. This experience can help drafters get a job. They may also be asked to submit a portfolio in order to demonstrate their drafting skills.

A certification is also available to drafters. American Design Drafting Association, (ADDA), offers certification tests that test drafting knowledge. These tests test your tolerance for geometric designs. Many certifications are valid for three years and require candidates to pass updated exams. The ADDA certifies a variety of drafting specialties.

Most drafters work in engineering, construction, or manufacturing. They may also work in factories, or with electrics. While they may work on a consistent schedule, some drafters work longer hours per week. They should also know how to manage their time and use computer-aided design (CAD).

Drafters can take advantage of a trend where more businesses are using technology to improve efficiency. To remain competitive, they will need to be able to use CAD and other software programs and keep up to date on building codes. A master's degree is an option for those who want to become a drafter. Those with a master's degree will have an edge over other candidates when it comes to getting hired. They are also more qualified to provide technical information to clients.

Drafters may also be able to work as an assistant for professional drafters. You can also volunteer to help on community projects. If you are interested in becoming a drafter, you should determine what type of project you are interested in before enrolling in classes. Some clients prefer pencil sketches while others prefer computer-generated designs.

Draft technicians can gain practical experience after graduating high school. They can enroll in drafting classes at technical institutes to get professional experience. They should also pay special attention to math and computer classes.

FAQ

What are the goods of logistics?

Logistics involves the transportation of goods from point A and point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

What is the responsibility for a logistics manager

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done through his/her expertise and knowledge about the company's product range. He/she should make sure that enough stock is on hand to meet the demands.

What is the importance of logistics in manufacturing?

Logistics are essential to any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics also play a major role in reducing costs and increasing efficiency.

Can some manufacturing processes be automated?

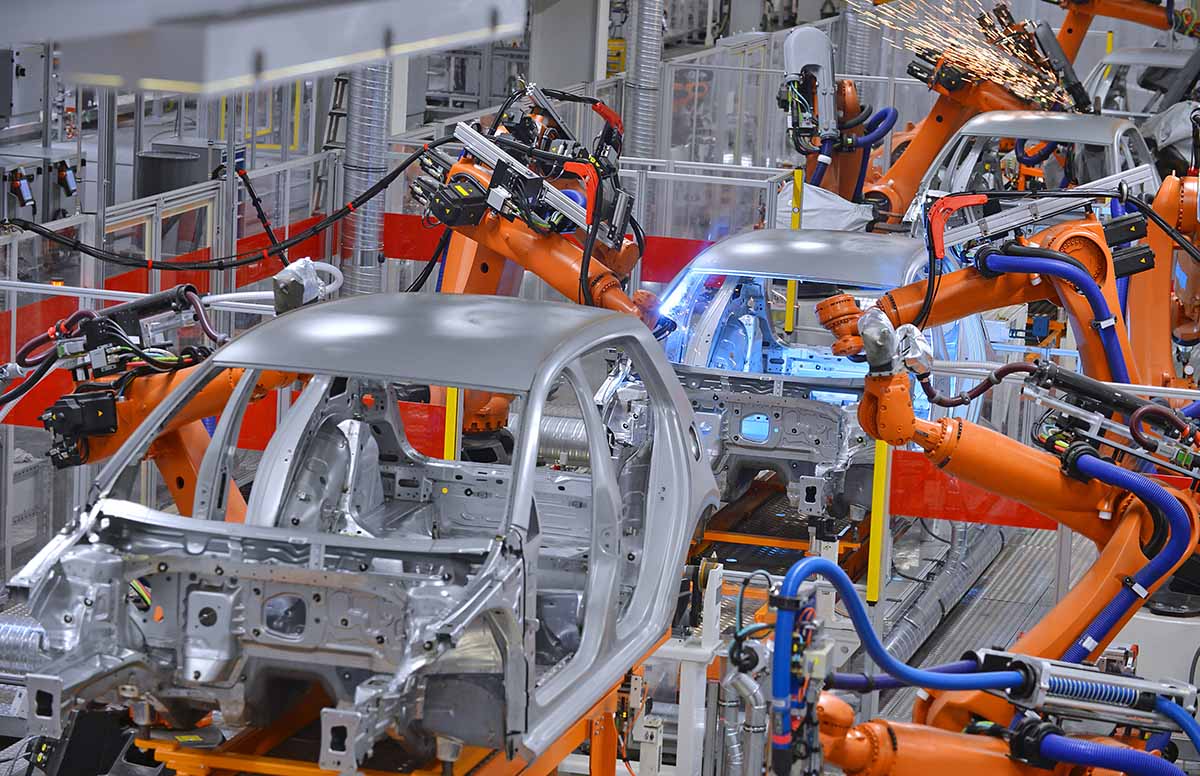

Yes! Yes. Automation has been around since ancient time. The Egyptians invented the wheel thousands of years ago. Nowadays, we use robots for assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

There are many other examples of how manufacturing could benefit from automation. 3D printing, for example, allows us to create custom products without waiting for them to be made.

What is the role and responsibility of a Production Planner?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. A production planner ensures that the service and product meet the client's expectations.

What is the job of a manufacturer manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should be alert for any potential problems in the company and react accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Is automation important for manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It enables them to provide services faster and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing can be found in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. To increase their competitiveness, many businesses have turned to lean manufacturing. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

You can apply Lean Manufacturing to virtually any aspect of your organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. Repairing a part that is damaged during assembly should be done, not scrapping. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous Improvement involves continuous improvement of processes.