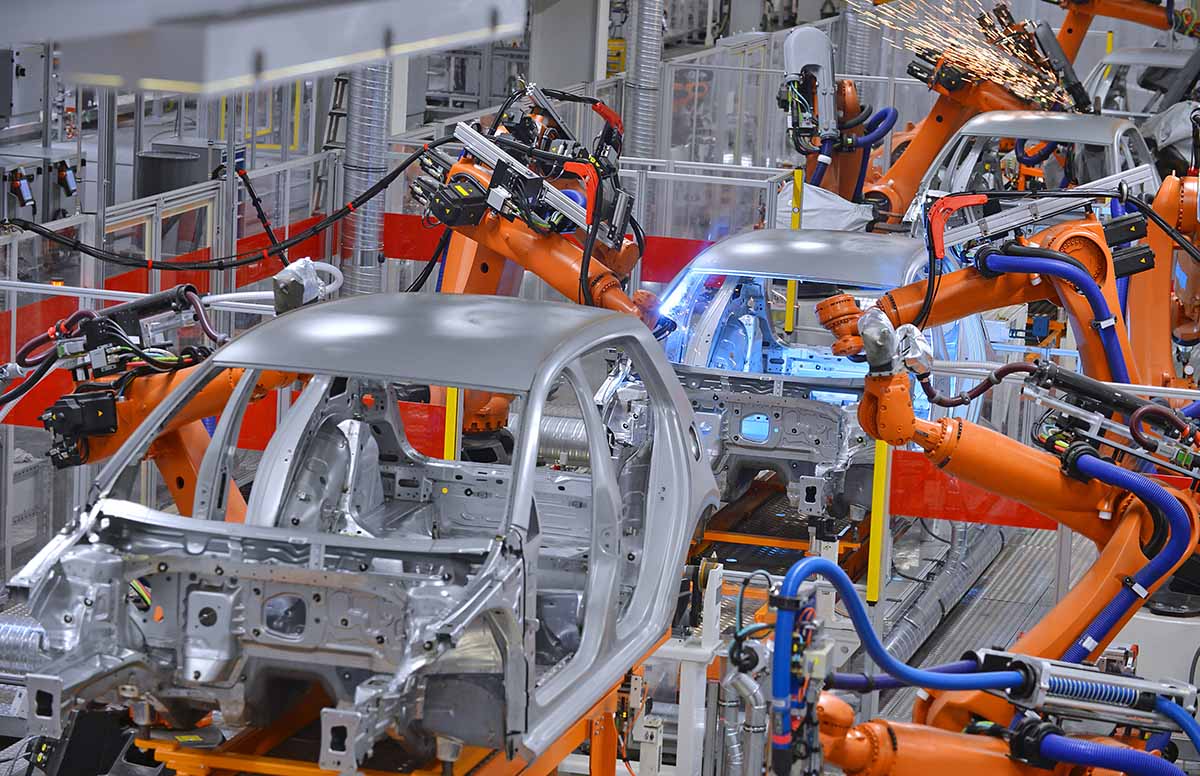

Industrial engineers develop efficient systems which integrate workers, machinery, materials, energy and information. They can also design products or services. Industrial engineers may work at an office or a production facility, like a warehouse or manufacturing plant.

Industrial Engineer Entry-Level in Texas

Your job as an industrial engineer is to ensure that production processes run smoothly. You will be responsible for analyzing problems, troubleshooting and implementing improvements to increase efficiency. You may also be responsible for training and supporting technicians who use systems and equipment that you designed.

The duties you perform will vary depending on what type of business you work for, and their requirements. Some manufacturers require that you develop a method for handling hazardous materials. Other manufacturers want you to create a system that monitors and controls the flow raw materials.

You may find yourself working with manufacturers to reduce waste during production. You could reduce the inventory in a storage facility, improve the efficiency of machines or identify and eliminate any wasteful practices.

You could work for a manufacturer of transportation equipment, or an electronics and computer firm. These jobs tend to be full-time. Employment is expected grow by 10% within the next 10 years.

Manufacturing Engineering Jobs Texas

If you want to get your foot in the door as an industrial engineer, you can begin with a position at a plant that manufactures heavy machinery or energy equipment. This is a great way to learn about industrial engineering, and many plant managers seek out candidates with this experience.

You will be required to attend training seminars and programs during your stay at the plant. These training opportunities will help you become a more productive member of the team, and you might be assigned to perform specialized research that helps you refine your skills as an industrial engineer.

Manufacturing Engineer at Eastman

If you have the right skills, Eastman Chemical could offer you a position as a industrial engineer in Mcallen. This is a rewarding and fast-paced job that gives you the chance to join a leading company in technology and energy.

As an industrial engineer you will be responsible for maintaining and implementing engineered labor standards at distribution centers all over the country. You will be an integral part of the team of industrial engineers, responsible for presenting engineering labor standards and distributing them to the associates of these facilities.

FAQ

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This is done through forecasting demand and identifying production capacities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

What does it take for a logistics enterprise to succeed?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. You will need to know how to interpret data and draw conclusions. You must be able to work well under pressure and handle stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You must be organized to meet tight deadlines.

What are the products of logistics?

Logistics involves the transportation of goods from point A and point B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

Why automate your warehouse

Modern warehouses are increasingly dependent on automation. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses should be able adapt quickly to new needs. In order to do this, they need to invest in technology. Automation warehouses can bring many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

It makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

High quality products delivered on-time

-

Removing human error

-

It helps ensure compliance with regulations

What are the 4 types of manufacturing?

Manufacturing is the process of transforming raw materials into useful products using machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use Just-In-Time Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It is a process where you get the right amount of resources at the right moment when they are needed. This means that you only pay the amount you actually use. Frederick Taylor, a 1900s foreman, first coined the term. He saw how overtime was paid to workers for work that was delayed. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. You will have the resources and people to solve any problems you anticipate. This will prevent you from spending extra money on unnecessary things.

There are several types of JIT techniques:

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. Here you can allocate certain resources based purely on demand. For example, if there is a lot of work coming in, you will have more people assigned to them. You'll have fewer orders if you have fewer.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT : This is the newest type of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your goal is to add value to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. This method is useful when you want to increase production while decreasing inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important because it reduces lead times and increases throughput.