The MIT Supply Chain Management degree program is highly regarded. Its enrollment ranks second to Michigan State's MS SCM. The students enrolled in this program come from many backgrounds and have diverse experience. Many of them hold post-graduate degrees. Students in the Supply Chain Class are extremely diverse. The easiest way to calculate the acceptance rate is by dividing the number of students admitted by the number newly awarded MM credentials.

The Supply Chain Management Program at MIT

MIT's Supply Chain Management program is an interdisciplinary degree program that draws business professionals from around the world. The program combines master's-level coursework with industry interaction and professional development. For more information, please visit the school’s website.

Online courses

You can improve your supply chain management skills, whether you're a novice or a veteran. These courses not only improve your career but also foster a sense o community. Allegue was able to expand her network and meet people from all walks of the globe by taking these courses. Allegue learned more about supply chains, and how they affect decisions.

On-campus program

The MIT supply-chain program is for students who wish to further their career in the logistics field. The curriculum emphasizes leadership skills and analytical problem-solving. It covers finance, database analysis, logistic systems, and finance. The program also includes a project in graduate research that requires students to collaborate with a partner company.

SCALE Centers

The MIT Center for Transportation & Logistics (SCALE) is one of the leading centers in the world when it comes to supply chain management. This center has been conducting research for nearly 50 year and has provided many companies with competitive advantage through cutting-edge research.

Scholarships

The MIT SCALE LA Scholarship is a merit based full tuition scholarship that will allow students at MIT to receive the award while they are pursuing their education. This scholarship gives students the chance to serve as class president, be part of MIT's GCLOG Team, and engage in the academic activities. To be eligible for the award, applicants must show financial need. The deadline to apply is November 15, 2020.

Fellowships

If you'd like to study supply chain management, you can apply for a Fellowship in the MIT Supply Chain Management program. This program honors exceptional students who have experience in supply chain management. The fellowships can be fully funded and pay full tuition to the successful candidate. The applicants must have two years relevant work experience and leadership potential. The admissions committee at MIT SCM works with AWESOME to identify the most promising candidates.

SCALE Connect conference at MIT

MIT's SCALE Connect conference, in collaboration with the Space Center Market Conference, brought together leading government officials, academics, and commercial industry representatives to discuss policy and learn about the latest developments in commercial space missions. The conference's main benefit was collaboration, as students had to participate virtually.

FAQ

What are the four types in manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

What is the responsibility for a logistics manager

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What is production plan?

Production Planning includes planning for all aspects related to production. It is important to have everything ready and planned before you start shooting. This document should also include information on how to get the best result on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

The first step is to decide what you want. You may have already chosen the location you want, or there are locations or sets you prefer. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. For example, you might decide that you need a car but don't know exactly what model you want. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

Once you have found the right car, you can start thinking about extras. You might need to have people in the front seats. Or maybe you just need someone to push the car around. Perhaps you would like to change the interior colour from black to white. These questions will help to determine the style and feel of your car. It is also worth considering the types of shots that you wish to take. You will be filming close-ups and wide angles. Maybe you want to show your engine or the steering wheel. These details will help identify the exact car you wish to film.

Once you have all the information, you are ready to create a plan. You can use a schedule to determine when and where you need it to be shot. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. This way, everyone knows what they need to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. It is not worth hiring someone who won’t show up because you didn’t tell him.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects may only take a couple of days, while others could last for weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple takes at the same place will result in higher costs and longer completion times. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is another important aspect in production planning. Setting a realistic budget is essential as it will allow you to work within your means. Keep in mind that you can always reduce your budget if you face unexpected difficulties. But, don't underestimate how much money you'll spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

What are the main products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They can also track shipments in transit and monitor quality standards.

What skills do production planners need?

A production planner must be organized, flexible, and able multitask to succeed. Effective communication with clients and colleagues is essential.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

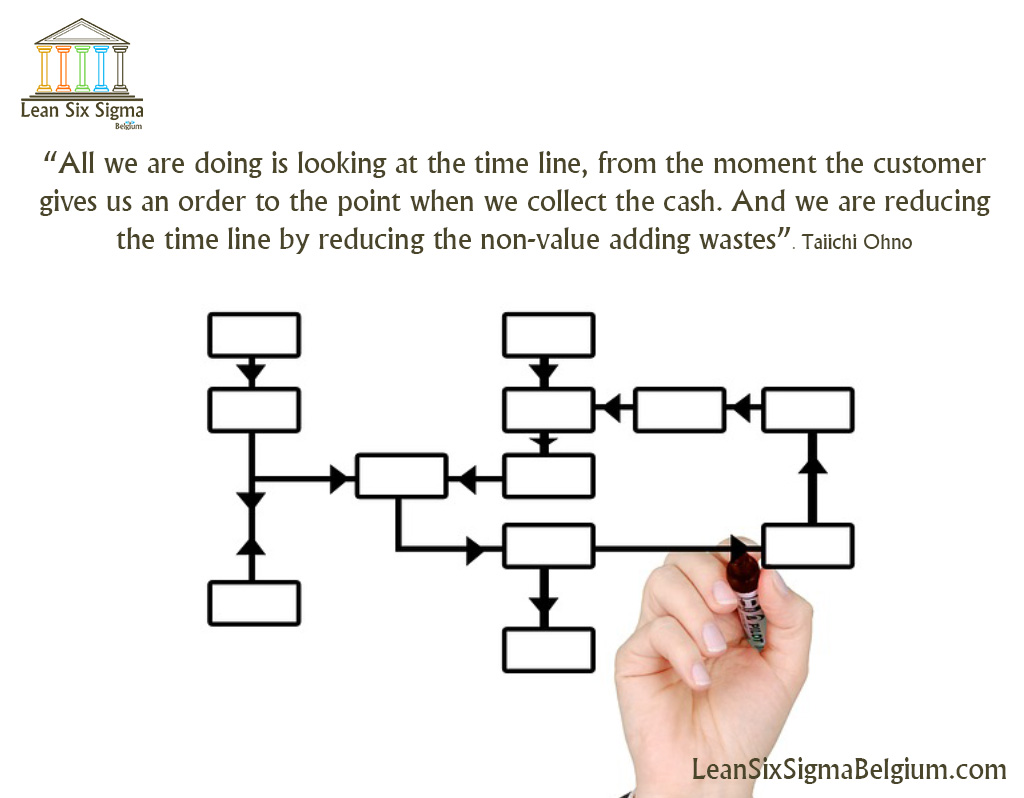

Six Sigma and Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If it is too large, it means that there are problems.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have this understanding, you will need to identify sources and causes of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. If you make widgets and some of them end up on the assembly line, then those are considered random variations. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you identify the problem areas, it is time to create solutions. That solution might involve changing the way you do things or redesigning the process altogether. Test them again once you've implemented the changes. If they fail, you can go back to the drawing board to come up with a different plan.