Getting goods and services from where they are to where they need to be can make all the difference in your company's success. Working with the best logistics firms in charlotte, nc is important.

Charlotte is a great place for logistics jobs in the United States, thanks to its location on the east coast and its advantageous infrastructure. The airport, the sixth busiest of the country, provides quick and easy access between Charlotte and other major cities in the US.

Transport and logistics are a diverse and lucrative industry. They focus on planning, buying, product assembly and distribution. It is an integral part of economy and growing job market.

In Charlotte, NC there are a variety of logistics positions. Supply chain management is the other name for this industry. It helps businesses increase their efficiency and profit.

Logistik offers a variety of warehouse and distribution services to businesses around the globe. It helps them move products from point A to B, regardless of their size or type. It is a third-party logistics (3PL) provider, and it has been in business since 1969.

With over 1 million square feet of warehouse space and 250 associates, it is one of the largest logistics providers in the area.

The company is a full-service logistics provider with a strong focus on delivering superior results.

Some of its clients are large commercial and retail enterprises in retailing, ecommerce (online shopping), manufacturing, technology, telecommunications, aviation and defense, life science, healthcare, and medical devices.

XPO Logistics is a leading provider of logistics services in the United States and Europe. They also provide comprehensive logistics and transportation solutions for businesses throughout Asia and Europe. XPO's global network includes over 60 offices with more than 1,000 staff in France Italy Spain Japan the U.S.A. and Canada.

They handle all types freight, including small parcels and large trucks. They are trusted by many leading brands including Disney, Pepsi Toyota, and L'Oreal.

NASCENT leads the industry in advanced technologies and intermodal solutions. NASCENT, a leader in advanced automation services, offers a broad range of solutions that can help businesses reduce costs while increasing efficiency.

NASCENT is a trucking company that offers traditional services. However, it also offers intermodal transportation, including services such as flatbeds, refrigerated trucks, and dry vans.

Customers of the company include retailers, distributors and wholesalers.

With a focus on security and compliance, GES has earned multiple certifications and provides an array of cargo security measures at its North American freight forwarding facility in Charlotte. These include closed-circuit camera monitoring and keypad access.

The company is also equipped with a robust technology infrastructure which allows them to offer their customers reliable, secure and cost-effective transportation solutions. This makes the company a preferred supplier amongst clients and ensures quality service.

FAQ

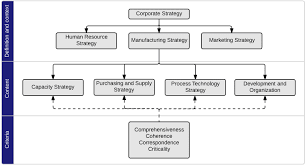

What is production plan?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also provide information about how best to produce the best results while on set. This information includes locations, crew details and equipment requirements.

It is important to first outline the type of film you would like to make. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. For example, you might decide that you need a car but don't know exactly what model you want. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you've found the perfect car, it's time to start thinking about adding extras. Are you looking for people to sit in the front seats? Perhaps you have someone who needs to be able to walk around the back of your car. Maybe you'd like to change the interior from black to a white color. These questions will help determine the look and feel you want for your car. The type of shots that you are looking for is another thing to consider. Are you going to be shooting close-ups? Or wide angles? Maybe you want to show the engine and the steering wheel. All of these things will help you identify the exact style of car you want to film.

Once you've determined the above, it is time to start creating a calendar. You can create a schedule that will outline when you must start and finish your shoots. The schedule will show you when to get there, what time to leave, and when to return home. Everyone will know what they need and when. If you need to hire extra staff, you can make sure you book them in advance. You should not hire anyone who doesn't show up because of your inaction.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects can be completed in a matter of days or weeks. Others may take several days. It is important to consider whether you require more than one photo per day when you create your schedule. Shooting multiple takes over the same location will increase costs and take longer to complete. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Another important aspect of production planning is setting budgets. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. Keep in mind that you can always reduce your budget if you face unexpected difficulties. It is important to not overestimate how much you will spend. You will end up spending less money if you underestimate the cost of something.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

What is the difference between a production planner and a project manager?

A production planner is more involved in the planning phase of the project than a project manger.

What skills do production planners need?

Being a production planner is not easy. You need to be organized and flexible. It is also important to be able communicate with colleagues and clients.

How can overproduction in manufacturing be reduced?

Better inventory management is key to reducing excess production. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. By doing this, we could free up resources for other productive tasks.

A Kanban system is one way to achieve this. A Kanban board is a visual display used to track work in progress. Work items are moved through various states to reach their destination in a Kanban system. Each state represents an individual priority level.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This allows them the ability to adjust their workflow using real-time data.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing emphasizes eliminating waste in all phases of production. Waste includes anything that does not add value to the product. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Can certain manufacturing steps be automated?

Yes! Yes. Automation has been around since ancient time. The Egyptians created the wheel thousands years ago. Robots are now used to assist us in assembly lines.

Robotics is used in many manufacturing processes today. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing can also be automated in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step involves a different action which leads to increased efficiency. For example, when you sort things, you make them easy to find later. When you set items in an order, you put items together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Make sure everything is correctly labeled when you label your containers.

This requires employees to critically evaluate how they work. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They must learn new skills and techniques in order to implement the 5S system.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They are more motivated to achieve higher efficiency levels as they start to see improvement.